Construct More Intelligent: How Aftermarket Construction Parts Can Boost Your Bottom Line

Construct More Intelligent: How Aftermarket Construction Parts Can Boost Your Bottom Line

Blog Article

Make The Most Of Efficiency: The Advantages of Making Use Of Aftermarket Components for Heavy Machinery

In the realm of hefty machinery maintenance and optimization, the application of aftermarket components has become a critical selection for several sector experts. The decision to integrate aftermarket components into heavy equipment elevates pertinent inquiries around performance improvement, cost-effectiveness, and long-lasting functional efficiency. As sectors continue to look for methods to boost the performance and durability of their hefty tools, the discussion bordering the benefits of aftermarket components comes to be progressively engaging. By exploring the subtleties of this different method to equipment upkeep, one can discover a world of opportunities that provide greater than meets the eye.

Cost-efficient Solution

An affordable approach to maintaining heavy machinery is by choosing for aftermarket components, which supply an economical remedy without endangering quality. Aftermarket parts are manufactured by third-party business as substitutes for initial equipment producer (OEM) parts. These parts are typically a lot more economical than their OEM equivalents because of competitive pricing and decreased brand costs. In spite of their reduced price, aftermarket components undertake rigorous testing to satisfy industry standards and ensure compatibility with various hefty equipment designs.

Wide Range of Options

In addition, the availability of aftermarket parts from several vendors and suppliers develops a competitive market that drives innovation and quality renovation - aftermarket construction parts. This competition benefits companies by providing them access to technically sophisticated components that may not be offered from original devices makers (OEMs) By having a vast array of aftermarket alternatives to pick from, organizations can maximize the efficiency, performance, and long life of their hefty equipment while maintaining expenses controlled

Improved Efficiency and Effectiveness

Enhancing heavy machinery performance and efficiency via the usage of aftermarket parts is a calculated strategy that several organizations are increasingly adopting. By including aftermarket components particularly made for hefty machinery, business can considerably enhance the total capability and efficiency of their equipment. Aftermarket components usually use sophisticated innovation and improved products compared to initial equipment manufacturer (OEM) parts, leading to boosted performance levels.

One trick facet of aftermarket components contributing to boosted performance is their ability to attend to particular concerns or weaknesses in the initial machinery layout. This targeted technique can result in much better overall performance, reduced downtime, and raised operational performance. Furthermore, aftermarket components are frequently crafted to provide far better sturdiness and longevity, additional enhancing the machinery's efficiency over an extended period.

In addition, aftermarket parts can aid optimize the machinery's gas consumption, resulting in set you back savings and environmental advantages. By fine-tuning the devices's parts, businesses can accomplish greater levels of effectiveness, translating right into boosted profitability and sustainability in the lengthy run. In conclusion, leveraging aftermarket parts to improve hefty machinery performance and effectiveness can provide an one-upmanship in today's demanding industrial landscape.

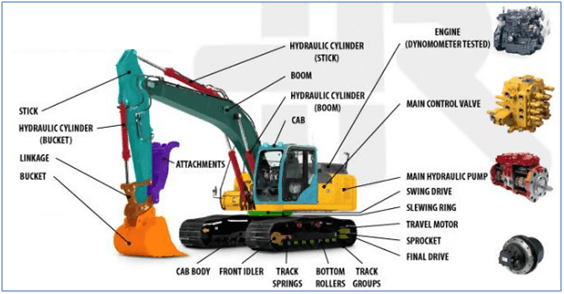

Raised Personalization Opportunities

Structure upon the improved performance and effectiveness attained via aftermarket components, heavy machinery operators can now discover raised modification possibilities to further optimize their devices. By integrating aftermarket parts that accommodate certain demands, drivers can adjust their equipment to execute tasks a lot more successfully and properly. These modification alternatives array from boosted engine parts to specialized add-ons that deal with special work demands. Drivers can set up custom-made exhaust systems to enhance airflow Discover More Here and increase engine efficiency, or they can choose for specialized containers and blades that are tailored to the type of product being taken care of. In addition, aftermarket components provide the flexibility to adjust numerous elements of the machinery, such as company website hydraulic systems, controls, and safety attributes, enabling a personalized approach to equipment optimization. This increased modification not just boosts the efficiency of heavy machinery yet likewise guarantees that drivers can adjust their equipment to fulfill the details needs of various projects, ultimately bring about higher productivity and cost-efficiency.

Extended Machinery Life Expectancy

Expanding the life-span of heavy equipment is an essential variable in making the most of operational performance and minimizing general maintenance expenses. By utilizing aftermarket components especially made for heavy equipment, equipment proprietors can considerably prolong the life of their equipments. Aftermarket parts are commonly engineered with high-grade products and accuracy, guaranteeing sturdiness and reliability. These parts can enhance the efficiency of hefty machinery, causing smoother procedures and reduced damage on crucial elements.

Aftermarket components use a cost-efficient remedy contrasted to initial equipment maker (OEM) components, allowing devices owners to preserve their equipments at a lower cost without compromising high quality. Additionally, the schedule of a vast array of aftermarket parts makes it easier to discover ideal replacements for various equipment models and brands, further supporting the durability of hefty tools.

Verdict

To conclude, making use of aftermarket parts for heavy equipment provides an affordable solution with a variety of choices my site that can enhance efficiency and effectiveness. These parts likewise allow for increased personalization opportunities and can add to extending the life-span of the machinery. Overall, integrating aftermarket parts right into heavy machinery repair and maintenance strategies can make the most of performance and maximize operational outcomes.

Aftermarket components are manufactured by third-party companies as replacements for original tools maker (OEM) components. Furthermore, aftermarket components come in various rate high qualities, ranges, and features, permitting organizations to select the components that best match their spending plan and efficiency demands.

Aftermarket parts commonly provide sophisticated modern technology and improved products compared to initial tools supplier (OEM) components, leading to boosted efficiency degrees.

Report this page